The post-processor makes the most of the settings of the sawing machines.Ĭollaboration with third party software Data from the different stores or productions can be exported or imported either in ASCII format, either in Microsoft Excel. Any kind of machines can be managed, each with their specific settings. Choice for first cut direction.Headcut manager.ĭata for cutting The sequences of sawing are either available as printouts and/or as numerical data. Technology Individual management of woodgrain drection.Layout of parts to facilitate the unload of the machine.

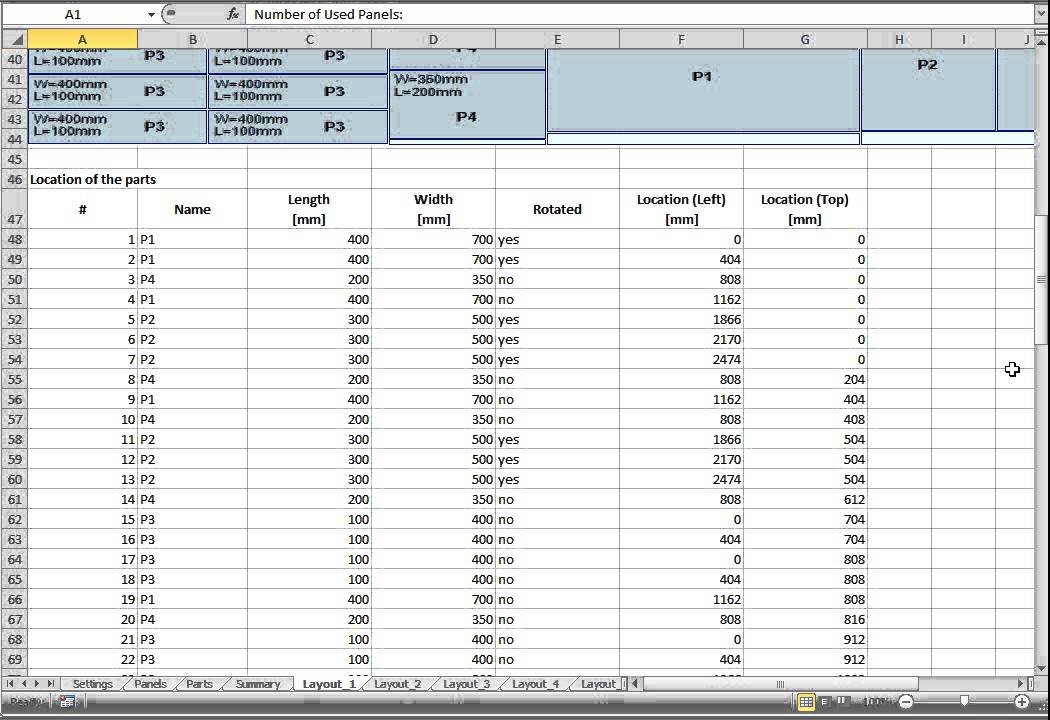

Taking into account the available board formats from the supplier or the best measures to get the minimum of scraps, the software can choose the best formats for a particular production. The operator selects among the proposed boards and their availability in the warehouse, the ones that reduce to a minimum the scraps, the time and the total cost of the production. All those tools will unload the necessary controls.īest format selection The optimizer brings the parts together according to the material, the thickness, the pattern. With the manual optimizer it is possible to manually intervene on the cutting patterns automatically generated by the software in order to insert or move some parts or to make up the boards with a high percentage of scraps.įor that kind of operation, the operator has at his disposal a set of tools to bring the parts together, or make them rotate or to copy and verify the feasibility. Optimization It returns the best solution taking into account the technical features of the machines, the saving of materials and optimal cutting patterns.

Blade thickness and grain direction are managed.Multi material/ multi thickness management.Choice between unlimited boards formats.WoodLAB PLAN is a cuting optimizer application for rectangular parts.Īn essential application to optimize cuttings > Allows TIME and OFFCUTS control WoodLAB PLAN is a cutting optimizer software for wood panels Next, a cutting list in ASCII format (.txt) will be made automaticaly available for importation in woodLAB PLAN. Once the project in woodLAB CAD is ready, the BOM is generated.

0 kommentar(er)

0 kommentar(er)